Home / QUALITY INSPECTION

QUALITY INSPECTION

QUALITY INSPECTION

Inspection and testing of machining process

Dimension inspection:

Yinxiao Manufacturing consistently high quality products requires good process control technology and advanced equipment.

Yin Xiao uses advanced inspection equipment and standards for the entire manufacturing and processing process, and our quality control department strictly follows the process to ensure that your parts meet the drawing requirements. We follow these steps for each project:

Chemical composition analysis of materials

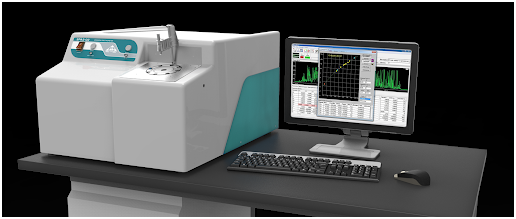

Equipment name: Spectrum analyzer

Basic working principle: It adopts Italian GNR spectrum analyzer, adopts vertical structure vacuum optical system, high stability spark excitation light source and high performance photoelectric detection device. It is a reasonable structure and better performance product in today's desktop spark spectrometer. It can be used in Analysis of Fe, Al, Cu, Ni, Pb, Zn and other matrix materials, 20 channels, can detect 20 kinds of metal elements at a time. The used METAL LAB software is a metal analysis software running in Microsoft Windows. It can not only store various data, but also perform data analysis and quality control. The working curve of the analysis program is drawn using international standard samples. For special alloys And elements can be drawn according to the standards provided by customers, and can also be translated into Italian, English, French, Spanish, German, and have tracing and standardization functions.

Function: Chemical analysis of materials

Profile Procontour Machine

ZSM contour projector, ZSM contactless contour measuring instrument, contour measuring industrial microscope, laser scanner and multi-induction head coordinate measuring instrument etc. other manual and CNC control high precision measuring instruments.

Testing of mechanical properties of materials

Equipment name: Universal testing machine

Basic working principle: WEW-600 microcomputer hydraulic universal testing machine adopts oil tank under, electronic force measurement, hydraulic automatic fixture for metal, non-metallic material tensile, shearing, compression, bending and other experiments. Its computer can perform data collection, Analyze, process, and automatically obtain parameters such as Fb, σs, σsu, σs1, σp0.2, σp0.05, σb, and modulus of elasticity E, which can display the experimental process data and curve dynamics, and perform experimental data editing, storage, and experimental results. Printing, accurately provide customers with the physical and mechanical properties of metal parts.

Features:

Testing of mechanical properties of materials, including tensile strength, yield strength, elongation, shrinkage

Testing the hardness of the product

Equipment name: Portable hardness tester

Basic working principle: TH110 portable Leeb hardness tester is mainly used for rapid hardness testing of metal materials, especially suitable for on-site hardness testing of large parts and non-removable parts. It can achieve six kinds of hardness (HL, HRB, HRC, HB, HV). , HS) and the conversion between hardness and tensile strength; it can display the measured value, average value, date, impact direction, number of tests, test materials, hardness system and other information; a host can be equipped with 7 different The impact device is used, no calibration is required during replacement, automatic identification can be entered for the test date and code; has a soft calibration function of the indicated value; a charge indication and low voltage alarm function; can print any test results; can automatically shut down; can replace the rechargeable battery In particular, in the inspection of metal raw materials, quality control of heat-treated workpieces, etc., it can provide formal original records that require test results.

Function: detect the hardness of the product

High-precision measurement of geometric elements such as size and shape

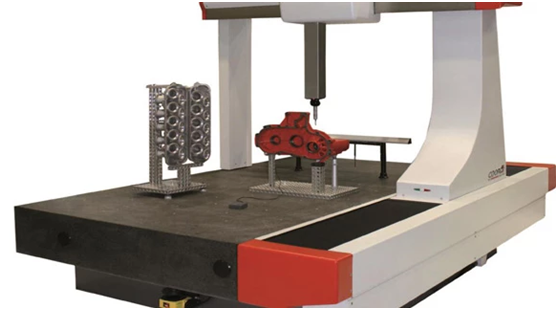

Equipment name: Coordinate measuring machine

Basic working principle: DRAGON series coordinate measuring machine is composed of a host (including the coordinate measuring host, machine support, imported precision air filter, imported foreign length measurement system), a computer system, a probe system (UK ), A set of measurement software packages (UK), with the ability to express in seven languages (including Chinese), can quickly complete the measurement and evaluation of geometric elements, shape errors, position errors, and can display three-dimensional solid models. DMIS3.0 standard, can communicate with the operator in the form of animation, sound, image, text, etc., can process the test results of any measured workpiece and output the test report. It can also output in point cloud format, IGES and other formats file.

Function: High-precision measurement of geometric elements such as size, shape and position

Detection of internal defects in castings

Equipment name: X-ray flaw detector

Basic working principle: this controller adopts a single and semi-controlled rectifier module. The rectified voltage changes into a smooth dc voltage after passing through the LC wave circuit. The voltage can be converted into a variable frequency unidirectional pulse through the SCR chopper loop and sent to the high-voltage pulse transformer as the power source of the X-ray generator. The milliampere stability unit can change the frequency of single pulse with the increase or decrease of the filament voltage of the X-ray tube to ensure the stability of the current of the X-ray tube. The kv regulating unit can continuously adjust the tube voltage to suit the requirements of different materials.

Function: detect inner defect of casting.

Measuring the surface roughness of machined parts

Equipment name: Surface roughness measuring instrument

Basic working principle: SRT-1 (F) portable surface roughness measuring instrument can measure the surface roughness of various machined parts, calculate the corresponding parameters according to the selected measurement conditions, and clearly display all the measurement results on the LCD display And graphics, can be output on a printer, and can communicate with a PC. The instrument can store the measured values and query the stored data.

Function: measure the surface roughness of machined parts.

Detects defects (e.g. cracks) on the surface and near surface of the casting

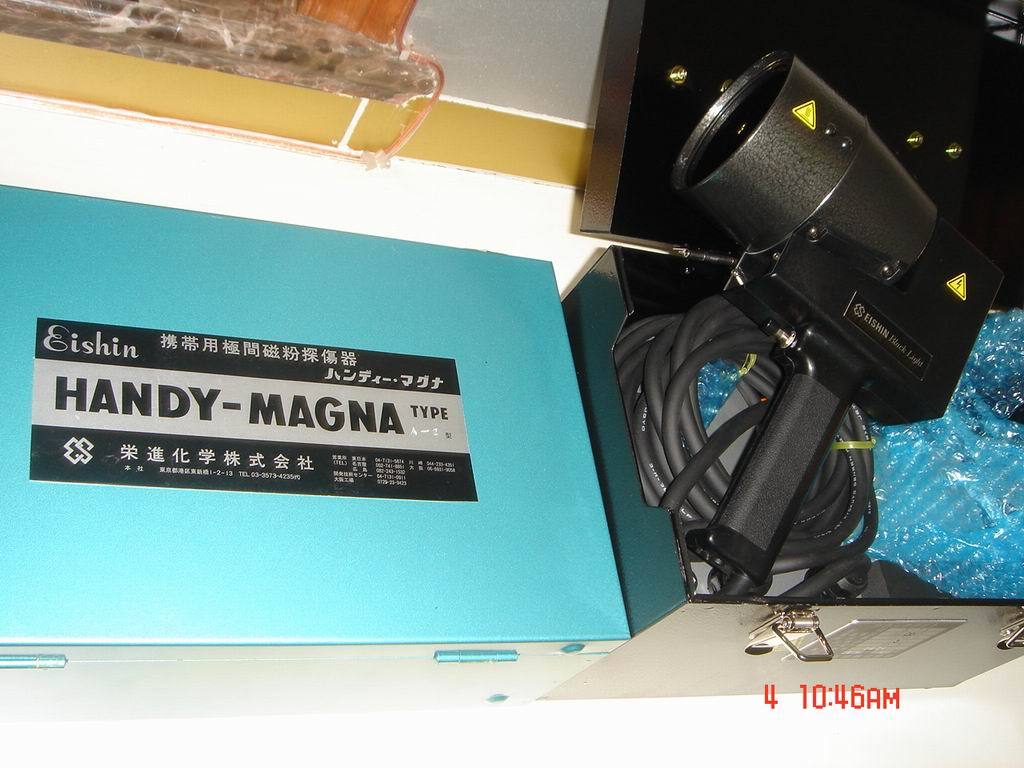

Equipment name: Portable magnetic particle flaw detector

Basic working principle: CJW-2000 magnetic particle flaw detector adopts the integrated structure of electromechanical instrument, which is mainly composed of magnetized power supply part and clamping rotation part; it can realize circumferential, longitudinal, composite magnetization and demagnetization of the workpiece, and the surface of ferromagnetic workpiece Defects near and near the surface can be inspected in all directions at once, and defects such as cracks and slag inclusions caused by casting, forging, quenching, and grinding fatigue can be found on the workpiece surface and near surface. If a dark room, ultraviolet lamp and fluorescent magnetic suspension are configured Fluorescent magnetic particle inspection is also provided with a "fault self-diagnosis" display function. The demagnetization energy on the machine automatically decreases from the used magnetizing current to zero, so that the residual magnetism of the workpiece meets the specifications.

Function: Detect surface and near surface defects (such as cracks)

Analysis of metallographic structure of castings

Equipment name: Metallographic microscope

Basic working principle: 4XC metallographic microscope objective lens is 10X, 40X, 100X, total optical magnification: 100X-1250X, is used to identify and analyze the structure of various metal and alloy materials; the quality of castings; Metallographic structure analysis after inspection or material processing; and research on surface phenomena such as surface spraying and cracks. If equipped with a camera, you can take a metallographic map and perform measurement analysis on the map, edit, output, Storage and management.

Function: Analysis of metallographic structure of castings

Yinxiao Manufacturing

Quality Service = Quality Products

Navigation

Copyright © 2026 Qingdao Yinxiao Machinery Manufacturing Co., Ltd. Support By BEE Cloud