Home / CAPABILITIES

Yinxiao Manufacturing

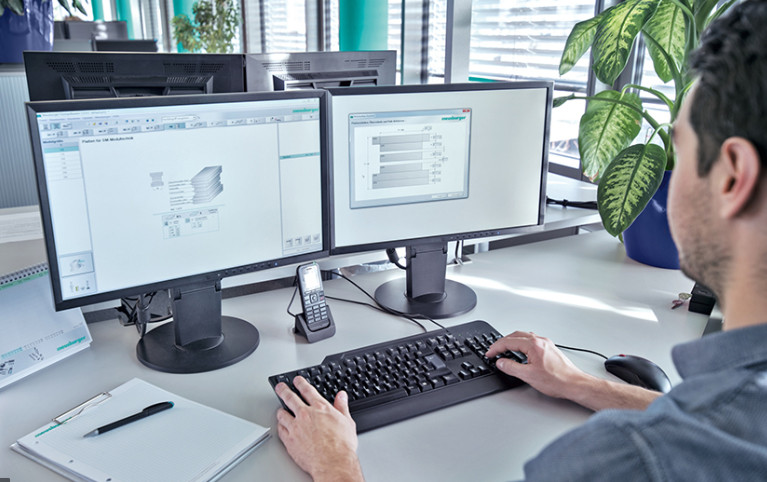

Quality Service = Quality Products

Navigation

Subscribe

Subscribe to our newsletter and we will inform you about newset products and promotions.

subscription

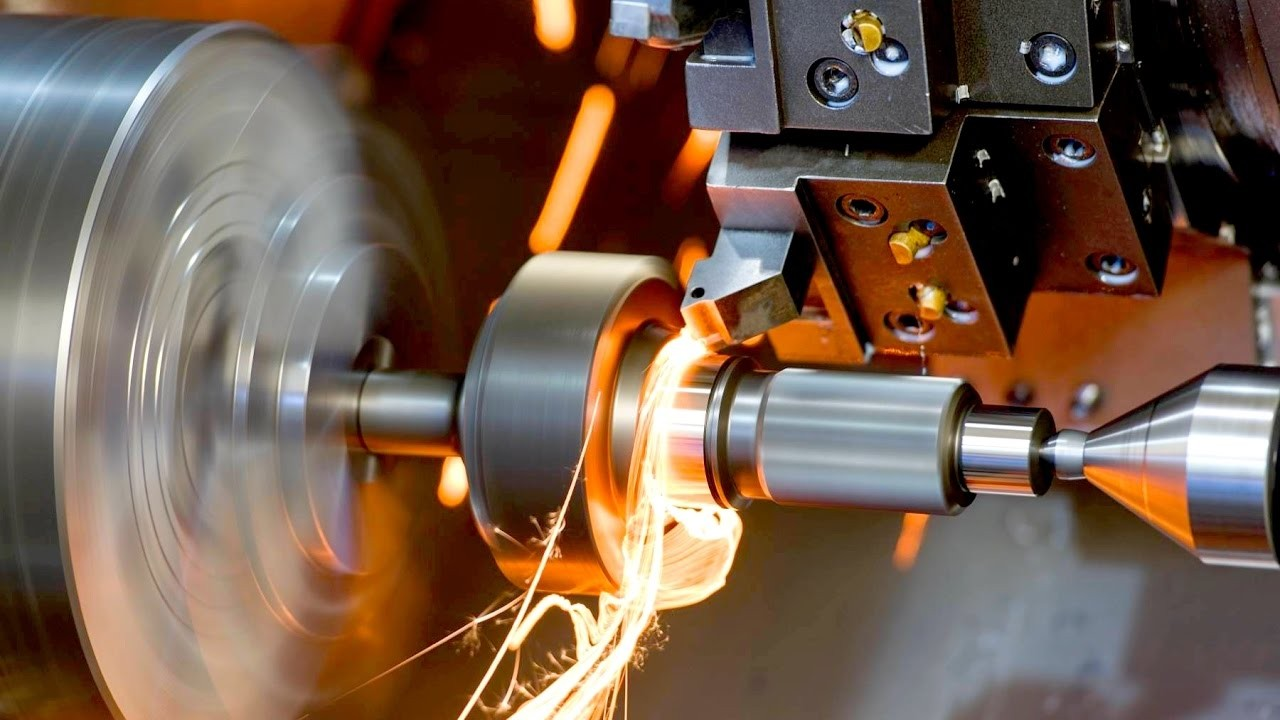

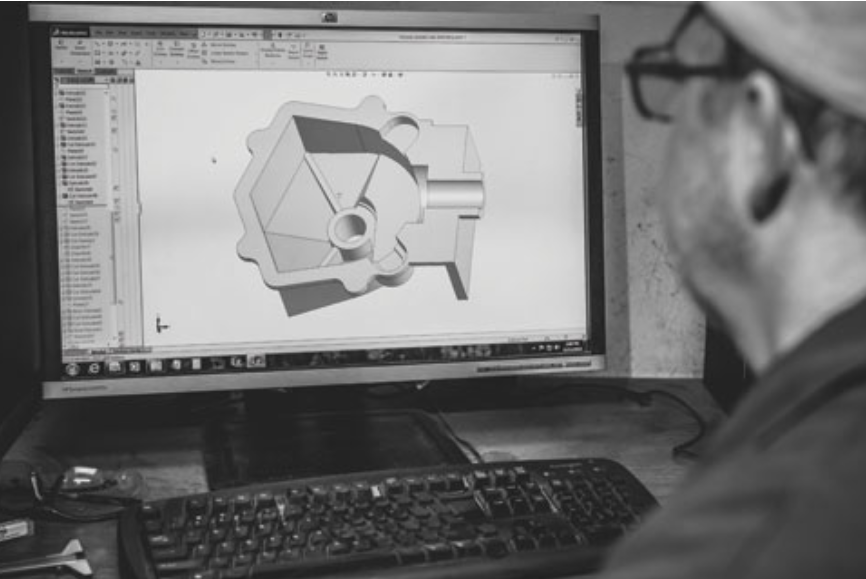

We can get the CASTING you need.