Home / All / Centrifugal Casting Parts / Custom High Precision Stainless Steel Centrifugal Casting Iron Parts for Furnace Rollers

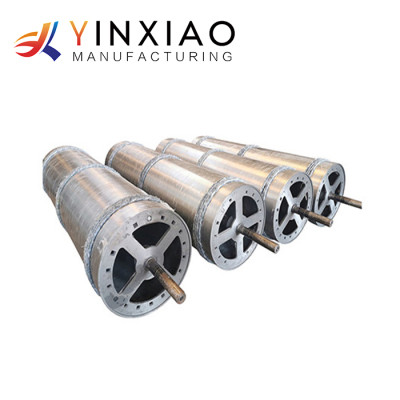

Custom High Precision Stainless Steel Centrifugal Casting Iron Parts for Furnace Rollers

| Share | |

|---|---|

| Categories | Centrifugal Casting Parts |

| Brand | YinXiao Metal Machining Manufacturer |

| Model | Furnace Rollers-1 |

| Certification | ISO9001:2015 |

| Brand | YX CNC Machining Parts Service |

| Material | Stainless steel,Aluminum |

| Process | Casting,CNC Machining,Turning,Milling,Hot Forging,Cold Heading |

| Package | Bulk packing , Cartons, Pallets, Wooden case |

| MOQ | 10 Pieces |

| Surface | No burr,Scratches,Dents,Pits,Oil stain |

| Specification | OEM part |

| FOB port | Qingdao |

| Terms of Payment | Western Union, T/T |

| Update Time | Feb 19,2026 |

Detail Information

PRODUCT DESCRIPTION

YX is committed to providing customized machining services for copper, iron, aluminum, stainless steel and other metal materials for 14 years. We can provide more accurate ODM service according to customer's design requirement. YX's market covers the United States, France, Belgium, Germany, Poland, the United Arab Emirates, Korea and other 26 countries. YX has a complete production and supply service system for precision casting,machining, hot forging, stamping, and laser cutting.We always insist on providing excellent products and value-added services for our customers.

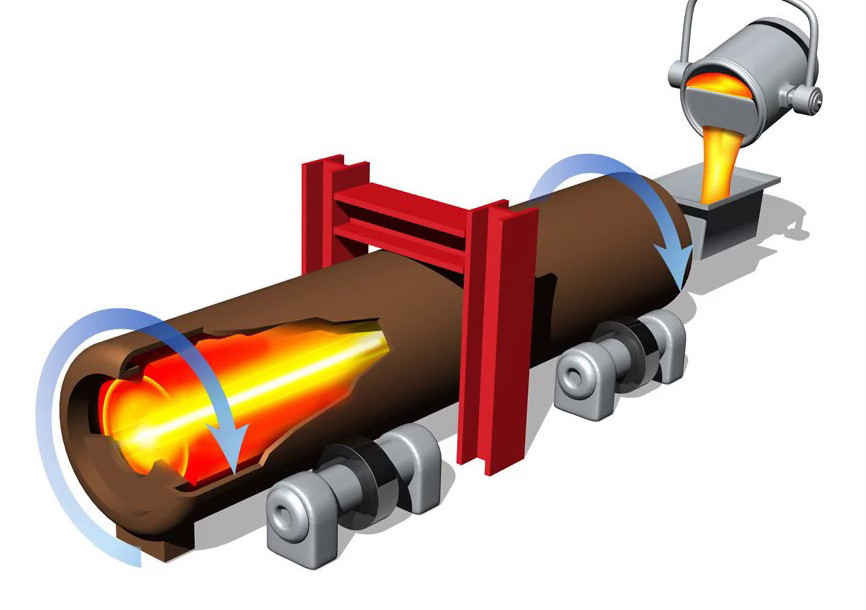

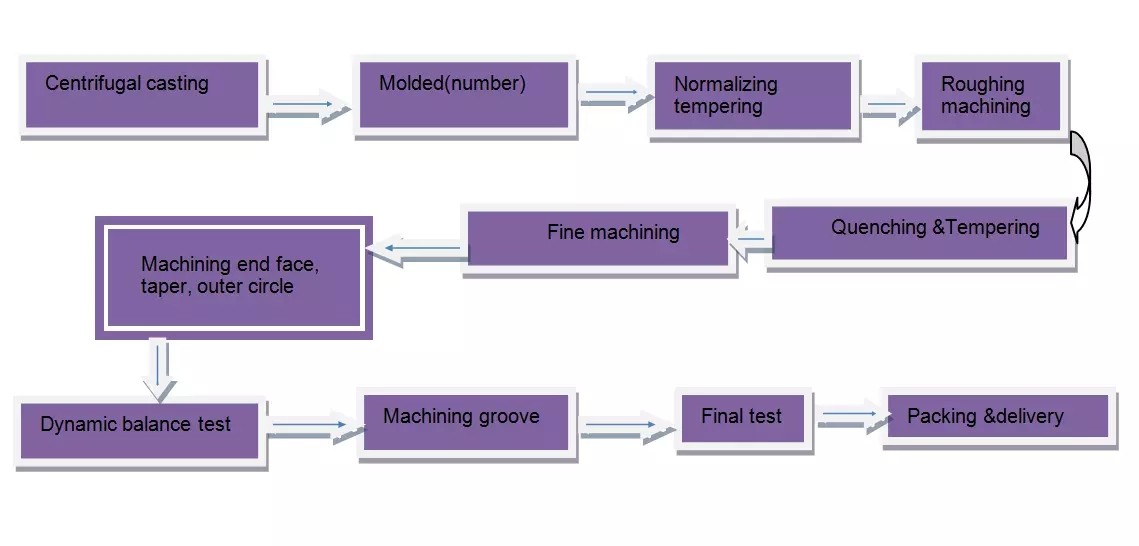

CENTRIFUGAL CASTING PROCESS

ADVANTAGE

►with good metal retraction and dense and the mechanical properties. Centrifugal casting roughcast will not be cracks, scum stoma and sandstone in its inner and outer surface

►The sleeve increased plasticity and toughness after quenching & tempering, and Improve yield strength and tensile strength, reduce elongation.

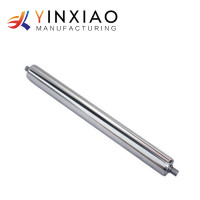

►Use the special tool to process end face, taper and the outer circle according to inner hole to ensure beating of the taper, the concentricity and cylindricity of the steel spool.

►Mechanical properties are almost equal to forging

►One-piece construction - always better than weld

►Saving cost beacause of long lifetime

►For the better world, recycled alloys will be used if the project suits

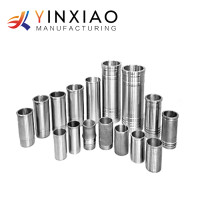

Dimensions of Centrifugally Cast Tubes/Pipes

►ALL ARE CUSTOMIZED

Lengths: Up to 4000 mm

Diameter: Up to 600 mm

Applications of Centrifugally Cast Tubes/Pipes

►WE'LL DO THE BEST TO ASSIST YOU WITH ANY CASE

Petrochemical, Oil & Gas, Automotive Industries

Others

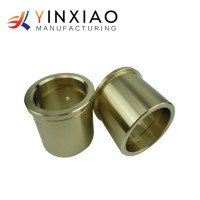

Materials of Centrifugally Cast Tubes/Pipes

►300 series, Duplex stainless steel, 17-4PH,Cast iron ,Aluminum alloy

MACHINING APPLICATION

Auto Parts

Construction Accessories

Heavy Machinery Accessories

Ranch Farming Equipment Accessories

Textile Machinery Accessories

Shippbuilding Accessories

PRODUCT DISPLAY

Related Products

Please send your message to us

- *Name

- *Phone

- *Title

- *Content

Yinxiao Manufacturing

Quality Service = Quality Products

Navigation

Subscribe

Subscribe to our newsletter and we will inform you about newset products and promotions.

subscription